HOLZ-HER LINEA 6015: From craftsmen for craftsmen.

Some call this special equipment.

We call it standard.

The HOLZ-HER LINEA 6015 pressure beam saw sets new standards in the economy class.

Most powerful saw motors in their class, rapid setup times for prescoring saw and gentle, scratch-free panel handling.

Numerous refinements in software and hardware will also convince you of the advantages of the LINEA 6015. To ensure the perfect quality of your cutting work, the LINEA 6015 provides everything as standard features, such as air cushions on the support and machine table or the prescoring unit with 2.2 kW of power.

The high acceleration values and cutting away from the stop fence are your guarantee for fastest cycle times and maximum process reliability.

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

Here is what the HOLZ-HER LINEA 6015 offers

- Saw Blade Protrusion up to 68 mm

- Sawing Unit: up to 11 kW

- Prescoring saw: 2.2 kW

- Cutting dimensions: 3,100 x 3,100 mm

Technical Details

Control Center

A perfectly designed workplace provides the basis for efficient, non-fatiguing work. With the 21.5" control terminal HOLZ-HER panel cutting saws satisfy all requirements placed by machine operators. The ergonomically adjustable and arresting shelf offers space for a label printer, scanner, keyboard and mouse within easy reach of the operator.

- The control center with large multi-touch 21.5” full HD monitor with 16:9 format guarantees maximum clarity with real time 3D graphics and full graphic finalization help.

- Standard equipment also includes a wireless mouse as well as a QWERTZ or QWERTY keyboard depending on the specific country.

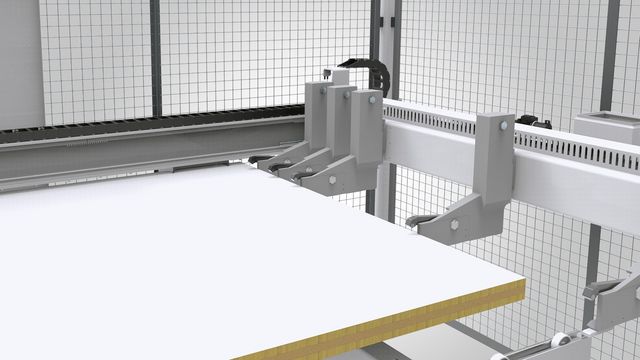

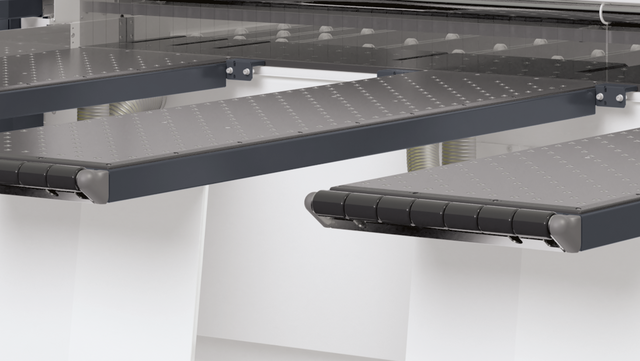

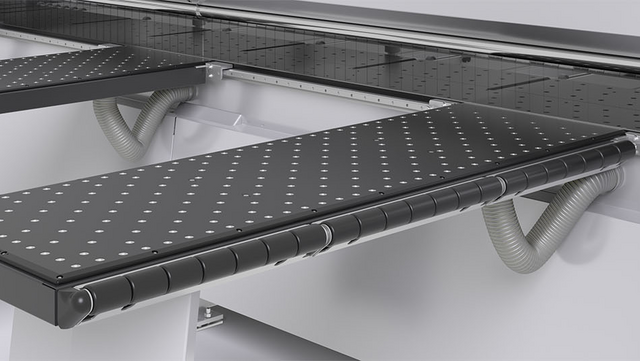

Solid air cushion tables

High functionality – perfect ergonomics

The LINEA 6015 meets the highest demands in terms of its technology and equipment.

- Air cushions for the machine table protect the workpiece during handling. A high power fan located aside in the rear corner of the machine (dust protection), provides a large area air cushion, allowing even heavy panels to be moved effortlessly.

- The stable air cushion tables (1,800x600 mm) never distort, even with heavy panels.

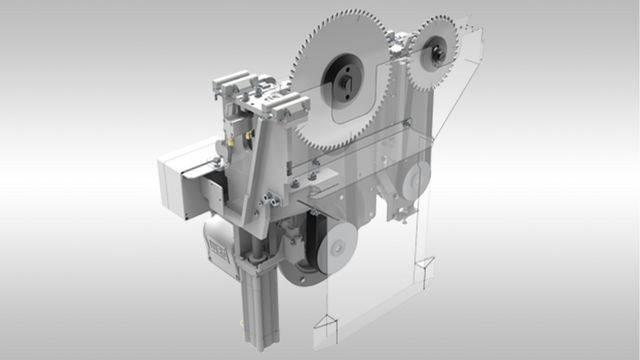

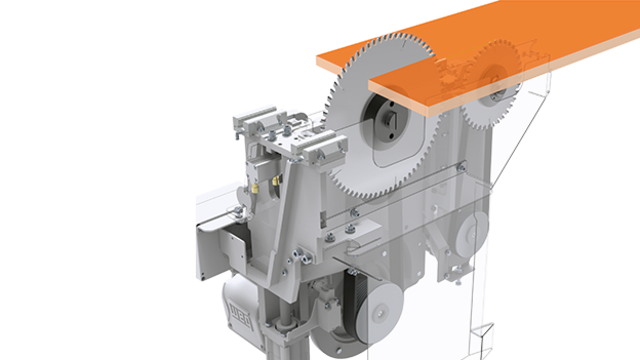

The LINEA 6015 sawing unit

- Main sawing motor – Provided as standard equipment with powerful 7.5 kW motor. For even more power the LINEA 6015 can be equipped with an optional high power 11 kW motor.

- Saw blade protrusion – Max. 68 mm for cutting single panels and stacks

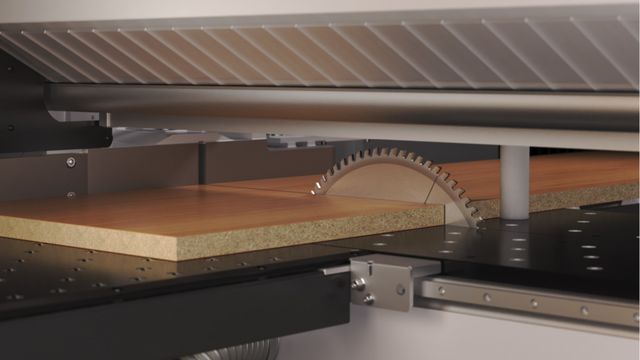

- Sawing carriage – The sawing carriage is equipped with a 300 mm primary saw blade and runs on linear guides, making it vibration-free and providing perfect precision for optimum cutting results.

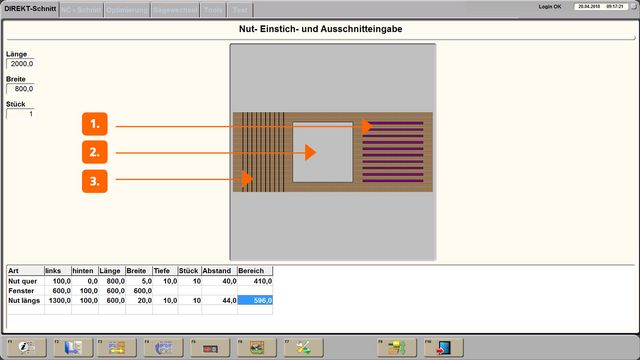

- Groove depth adjustment–The groove depth is manually adjustable from 0 - 25 mm; the groove positions and dimensions can be programmed using the control as well as the optimization feature.

- Bidirectional grooving program (FCM) Fast Cut Mode– Ensures extremely short cycle times for grooving, whereby a groove is also cut as the sawing carriage moves back.

- Automatic cutting length limitation – A proximity-type optical feature recognizes the end of the workpiece - eliminating unnecessary sawing carriage travel, especially for manual cuts.

- Optimized automatic cutting length feature – The sawing carriage is controlled by the optimization feature - the sawing carriage is prepositioned beneath the panel, the start and end of the cut are calculated, paths without cutting are traversed at maximum speed.

- Prescoring saw – The prescoring saw’s powerful 2.2 kW motor easily scores even hard decorative surfaces such as HPL. The software controls the unit for adjusting the prescoring saw blade. The height and lateral adjustments can be made manually with the tool running. This allows simple and perfect adjustment of the prescoring saw on the monitor, in the shortest possible time, with minimum effort.

- Quick-change clamping system for main and scoring saws - Ensures precisely clamped saw blades and extremely short standstill times for changing saw blades.

Prescoring saw

The prescoring saw on the LINEA series has an output of 2.2 kW for hard coatings and materials.

The adjustment concept promises extremely high speed setup and adjustment times. The prescoring saw can be adjusted while running.

Inspection & storage access door

A double sliding door provides access to the rear of the machine.

The sliding door moves on precision linear guides. Space for up to 6 Euro-pallets is present in the rear area of the machine below the roller tracks. The perfect access for service and cleaning work in the rear area of the pressure beam saw.

The access can be installed on the right or left as desired.

Single Press - Angle pressure device

The rubber-coated side pressure roller is prepositioned by the optimisation feature to lower immediately in front of the workpiece. This ensures maximum performance when cutting panel strips to length. The side pressure is applied by the solid linear guides.

Line laser for cutting line

The Visible Cut Line uses a laser beam to indicate the exact cutting line. This also allows cuts according to a manual sketch to be positioned and cut perfectly. Naturally this device also provides a major advantage when cutting real wood (e.g. edging).

Freely programmable rip fence

Workpiece clamps with optional floating design compensate for tension in the panel stack toward the top.

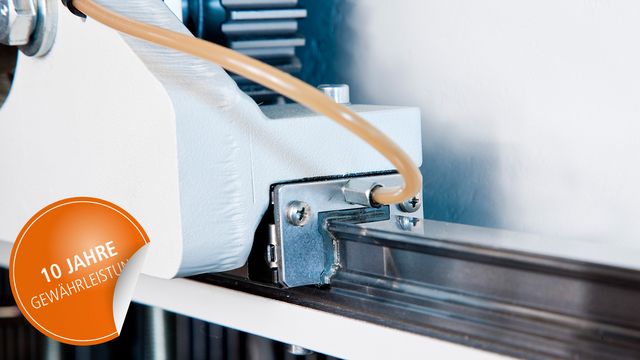

Stable, welded construction with precision, hardened linear guide ensures precise, smooth running. Direct rack-and-pinion drive (upright shaft) and proximity-type sensor for absolute dimensions guarantee maximum positioning accuracy. The servo-technology motor moves the fence quickly to the selected positions. The measuring system is equipped with a CC (Continuous Checkup) mode for continuous, autonomous checks.

High quality components such as covered, hardened and ground linear guides on all axes ensure many years of precise and reliable operation. Optimized, extremely rigid machine and traveling columns for excellent machining results.

Only with HOLZ-HER:

- 10 year guarantee on all linear guides!

Workpiece clamps

Perfect hold - HOLZ-HER workpiece clamps

The first three workpiece clamps on the LINEA 6015 are located close together especially for cutting strips. The clamps are optionally available with a floating mount on a linear guide allowing them to compensate irregularities in the panels/stacks. Optional controlled stops are available for precise cutting on veneered workpieces.

Remnant cutting device for division without remnants. The clamps retract into the grooved pressure beam. Panels can be used completely during processing.

Remnant cutting device integrated into the pressure beam

The clamps move forward right up to the cutting line.

Panels can be cut without waste, allowing utilization of the entire panel during machining. During scratch cutting the sawing carriage regulates the feed rate fully automatically for a clean cut.

Infinite clamping pressure

A pressure gage on the front of the machine allows infinite adjustment of the clamping pressure. This is gentle on sensitive and soft materials.

Charging rollers

The solid, industrial class charging rollers can be attached to the machine tables at the front as well as along the side for charging with a panel cart or with the stacker.

Hand-held control unit

For remote control and easy machine operation.

The clamps can be opened or closed from all positions. Moreover the sawing cycle can be started or discontinued from any position around the machine. The user can control the materials in every situation.

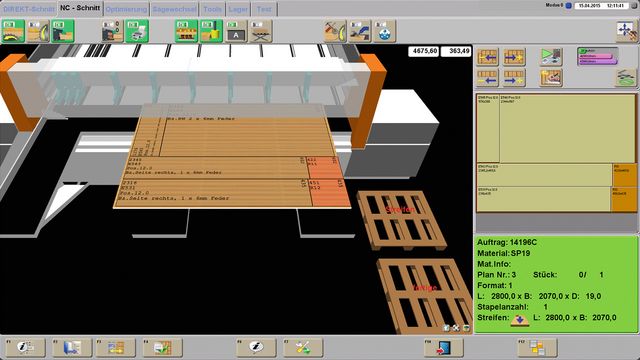

The CUT CONTROL 2 control package

The high performance software package for HOLZ-HER industrial saws

The control is decisive for the power output of a state-of-the-art pressure beam saw. All HOLZ-HER panel cutting saws are equipped with our CUTCONTROL 2 and the preinstalled EASY-PLAN and OPTI-CUT software packages.

Everything at a glance:

- The self-explanatory graphical user interface ensures that your employees can start operating the machine quickly and properly without any major training.

- The optimized information display ensures maximum "clarity" (buttons and features not required are hidden).

- EASY-PLAN optimization software preinstalled at the factory.

- Individual jobs can be assigned a priority at any time, job programming parallel to cutting.

- Graphic 3D user interface for intuitive operation and machine sequence functions for NC cutting.

- Program-controlled measurement of reference dimensions when saw blade is changed.

- Information display indicating running meters for main and prescoring saws.

- Individual adaptation of function and parameter settings.

- Operating states, service and maintenance intervals as well as separately programmed energy management are displayed in real time.

Technical Details

Maximum efficiency with Holz-Her machine networking

HOLZ-HER realizes your production ideas within 20 minutes from the first mouse click to finished furniture with seamless machine networking.

Energy savings made easy

The intelligent ECO MODE energy management for HOLZ-HER CNC machines not only helps preserve our environment - it also saves you money.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

Technical Data (PDF, 8 MB)