CNC machining center EPICON 7135 SpaceSaver: The 5-axis space-saving miracle

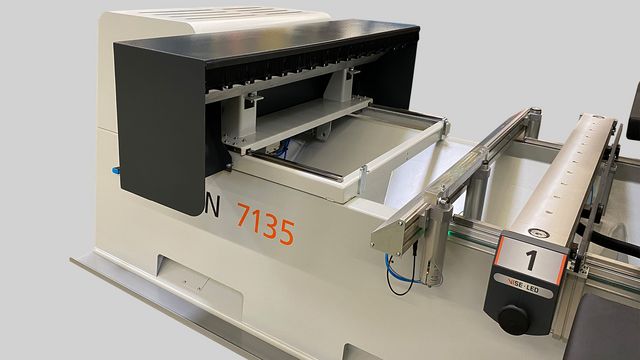

With the new EPICON 7135 Space Saver, HOLZ-HER presents a revolutionary solution for 5-axis CNC machining - compact, powerful and well thought-out down to the last detail. Thanks to the innovative bumper technology, the machine offers maximum safety without the need for complex protective enclosures such as step mats or safety fences. The result: maximum flexibility in positioning - even directly against walls or in corners.

The 360° access concept allows free access from all sides - ideal for maintenance, servicing and material handling. The space in front of and behind the machine remains fully accessible, making loading and unloading particularly efficient. Generous doors at the front and rear also ensure optimum access to the processing head.

The sophisticated machine design fully integrates the vacuum pump, tool changer and control cabinet into the housing. With a compact footprint of just 6,600 mm in length and 3,150 mm between the fences, the EPICON 7135 SpaceSaver offers an ideal solution for companies with limited space - and impressive performance at the same time. The machine is delivered almost completely pre-assembled, which significantly reduces installation time at the customer's premises.

With its powerful routing spindle, precise 5-axis head and flexible choice of table versions - from the standard console table to the intelligent VISE LED table - the EPICON 7135 covers a wide range of applications. Whether solid wood, panel material or composites: this machine delivers top performance in the tightest of spaces for demanding applications in furniture construction and interior design.

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

Here is what the HOLZ-HER EPICON series offers

- CAMPUS Machine Control

- With 5 interpolating axes

- Effective machining height up to 300 mm

- 10 year guarantee on all linear guides

- Machining in X direction: up to 7,280 mm

- Machining in Y direction: up to 2,100 mm

What the EPICON 7135 Space Saver has to offer

- Powerful 5-axis spindle

- Enclosed vacuum pump

- Flexible table concepts

- Full Bumper security technology

- Permanently mounted switch cabinet

Technical Details

Flexible installation scenarios with 360° access

Compact, powerful and well thought out

Thanks to the innovative bumper technology, the machine offers maximum safety without the need for complex protective enclosures such as safety mats or safety fences.

The result is maximum flexibility in positioning, even directly against walls or in corners. The 360° access concept allows free access from all sides and is therefore ideal for maintenance, care and material handling. The machine is operated from the front.

To further simplify transportation, the control cabinet and vacuum pump are already permanently mounted on the machine frame.

"Easy Start" start button

Short distances and high efficiency

Enables convenient operation and short distances thanks to additional start buttons on the machine bonnet. This is an indispensable option, especially for pendulum machining and in combination with the 7135 Space Saver.

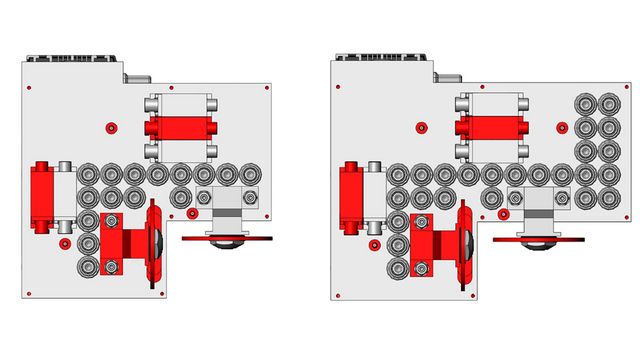

Tool changer variants

Performance-orientated solutions

The EPICON 7135 Space Saver is already equipped with a travelling 18-position disc changer as standard. In addition to shank and profile tools, this can also accommodate saw blades with a diameter of up to 350 mm!

A linear changer, which is permanently mounted on the left-hand side of the machine, is available as an option for even more tool positions. The linear changer can be equipped with up to 16 additional tools.

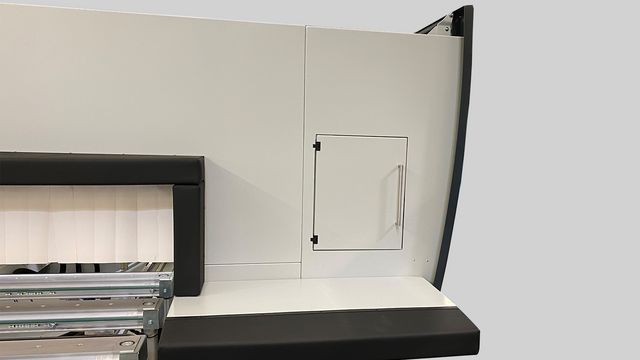

Side access door

Easy access

To allow easy access to the traveling tool changer, even when the machine is positioned against the wall, there is an access door on the side of the machine.

This allows the tools to be loaded quickly and safely by hand.

Enclosed vacuum pump

To further reduce the installation dimensions of the machine, the vacuum pump was mounted on the left-hand side of the machine frame and enclosed.

The pump is already installed and connected during transport.

Powerful 5-axis cutter unit

Proven 5-axis technology - including Beckhoff drives and control

The fulling interpolating 13 kW, 5-axis spindle (standard feature) runs on both sides in ceramic bearings, ensuring extremely high drive holding forces.

For extreme machining work on solid wood the optional PRO torque spindle is ideal. With an output of 18 kW and mechanical brakes on the A and C axes, this machine provides for extreme rigidity and perfect results at high feed rates with maximum chip removal.

Bluetooth Monitoring Chip

ChipControl - Bluetooth spindle sensor to prevent spindle damage caused by vibrations or overheating.

- Warning messages when defined vibration and temperature thresholds are exceeded

- Real-time visualization of the data on the operating terminal enables fast and precise monitoring

- Increased safety by logging peak values that may indicate a collision. These are displayed in the peak counter.

Perfect in combination with the viaCockpit digitalization package and the option of displaying these messages on the viaCondition module of mobile devices for prevention purposes.

CAMPUS 5-axis module - 3D simulation

3D material removal simulation as standard feature

Even the basic versions of the EPICON machines are equipped with our mature 3D material removal simulation feature. The CAMPUS 3D machine simulation can be ordered as an optional feature. This offers:

- Collision monitoring

- Three-dimensional simulation of machine motions and material removal on workpiece

- Graphic representation of machining head, tool and tool collet, table and clamping device.

- Upgrade is possible to the machine simulation described above with display of consoles, suction cups and clamps.

Perfectly optimized 5-axis cutting with the high speed curve performance package

The standard High-Speed-Curve Performance package offers 5-axis power users additional benefits. It utilises the first-class performance of the 5-axis spindle for real high-speed milling with perfect results. The high-speed module is also ideal for boosting performance when connecting to third-party CAD/CAM software and offers perfect spline interpolation.

CAMPUS 5-axis module for simultaneous cutting

The NC HOPS supplement module supports interpolating 5-axis machining in many areas such as:

- 5-axis simultaneous cutting.

- Support of 5-axis interpolation with top and bottom guide curves (simultaneous machining).

- Two contours on defined layers are interpreted as 5-axis machining.

Integrated drilling head with 14 | 21 | 31 spindles

The EPICON 7135 is perfectly equipped with integrated drilling heads.

14 spindles

- Drilling unit with 10 vertical spindles

- Four horizontal spindles (can be upgraded with third additional horizontal spindle in the X direction and second horizontal spindle in the Y direction).

- Integrated grooving saw in X direction (optional second grooving saw in Y direction)

21 spindles

- Drilling unit with 15 vertical spindles

- Six horizontal spindles (can be upgraded with third additional horizontal spindle in the X direction and second horizontal spindle in the Y direction).

- Integrated grooving saw in X direction (optional second grooving saw in Y direction)

31 spindles

- Drilling unit with 25 vertical spindles

- Six horizontal spindles (can be upgraded with third additional horizontal spindle in the X direction and second horizontal spindle in the Y direction).

- Integrated grooving saw in X direction (optional second grooving saw in Y direction)

Machining head - optimized for practice

Drilling, sawing, cutting, grooving – the machining head on the EPICON series is equipped for multifunctional use and is perfect for rational production of simple and complex case parts in continuous operation.

The integrated and compact design makes this machining head a paragon for dynamic action, acceleration and positioning accuracy. Even in the basic equipment, the EPICON series offers a wide machining spectrum.

Highly flexible machining tables

Standard: Console table – the workpiece support for optimum work progress

Precise machining requires exact and secure positioning of the workpieces. For this purpose, the EPICON series is equipped with a console table. It offers maximum flexibility in all areas of machining; even workpieces with complicated shapes can be clamped quickly and easily.

- Solid consoles with single circuit vacuum system, six easily movable cross-members – with pneumatic clamping feature in X direction. Both right-handed and left-handed users can easily operate the consoles pneumatically at the touch of a button.

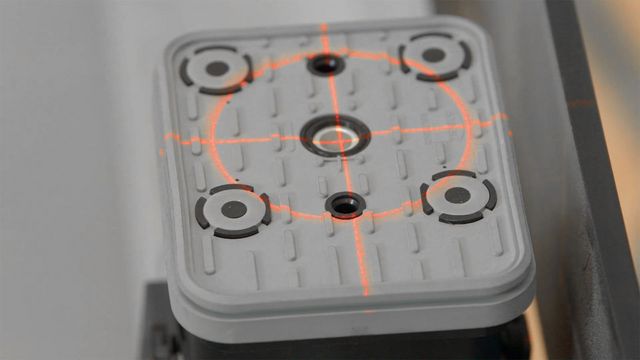

- Measuring tapes in the X direction for quickly positioning consoles, laser pointers for precise position of suction cups. Other consoles and suction cups available as options.

- 125 Millimeter high suction cups provide machining head with sufficient clearance on all sides.

- Moving stops, eccentric in hardened guide bushings. Stops can be lowered pneumatically.

- Four pneumatically operated charging aids can be raised and lowered to position heavy workpieces easily. Additional charging aids available as options.

- Two large surface pushbuttons for clamping.

- Additional processing fields for higher capacity (optional).

- Individually switchable vacuum zones prevent vacuum losses.

- High performance vacuum pumps – 100 m³/h.

Optional: Vacuum pumps for 140 m³/h and 250 m³/h.

SynchroDrive machine table

State-of-the-art production technology with up to 50 servo-axes

For high speed, precise and reliable suction cup positioning on workpieces with varying sizes:

- Optionally available with six to ten consoles and three or four suction cup assemblies per console

- Each console and each suction cup assembly has its own high precision servo-motor for positioning

- Up to 50 servo-axes on the SynchroDrive table are synchronized, controlled and positioned to reduce table set-up times to an absolute minimum while simultaneously ensuring exact positioning of the consoles and suction cups on the table

- Various suction cup sizes as well as special suction cups for solid wood and frame clamps adapt the SynchroDrive table to every application

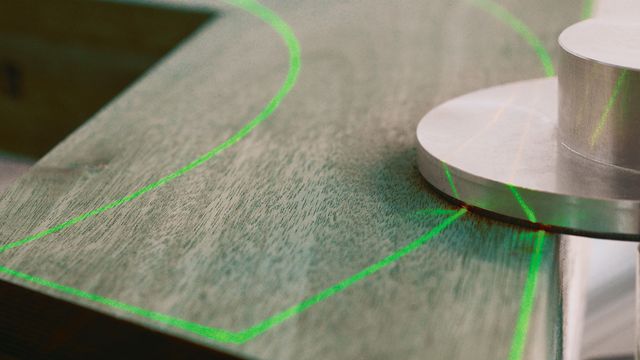

VISE LED Table

At HOLZ-HER, VISE stands for Visual Setting, providing visual support for the machine operator when setting up the machine. The virtual workpiece positioning feature provides an optimum recommendation for the position of the consoles and suction cups.

Naturally the tools used, as well as the passages, pockets and other machining features are taken into consideration.

The HOLZ-HER LED table with Visual Setting ensures extremely fast, error-free and reliable setup while avoiding machining errors and damage to the suction cups.

Well-thought-through workpiece clamping

CNC machining centers are becoming ever more efficient with the use of intelligent software combined with proven technology. One-piece complete production is now the measure of all things. All parts must be produced to the highest quality standards and with all conceivable processes in a single pass. The concept of "more product capability" opens new horizons. In addition, CNC machining also ensures the resurrection of traditional woodworking joints. Where earlier manual methods involved high-cost processes and large tolerances, these days it's only a matter of a few clicks of the mouse and complex joints are created to the highest levels of precision. In this way, mortised frame doors and swallow-tailed connections are being rediscovered.

Variable system of matched suction cups and workpiece clamps for surface machining including straight and curved frame parts.

Intelligent solid wood machining

The EPICON series offers virtually unlimited possibilities for machining. Constructed for the most highly demanding work, the solid and well-thought-out construction of both machines represents the latest in modern and application-friendly industrial design.

The extreme machining lengths in the X direction make the console table on the CNC machining centers ideal for machining long parts such as components for stairs, winter gardens, etc. Even large door components can be machined in a highly efficient and trouble-free manner in pendular operation. With up to 1,650 mm in the Y direction as well as a Z stroke of 565 mm, the EPICON is perfectly equipped for highly variable, custom machining operations.

Innovative changeover units

Your advantage for high product quality

A variety of changeover units for highly varying applications is available for all machines in the EPICON series. These range from conventional multi-spindle machines, lock box and sawing units to special applications such as hollow cutting chisels and cutting units for machining foam materials, etc.

Angular slewing gears with angle display and central angle adjustment are available for precision angle cuts and holes.

In addition ball measuring sensors ensure precise measurement of the workpiece length, workpiece depth and material thickness including workpiece position correction in the machining program.

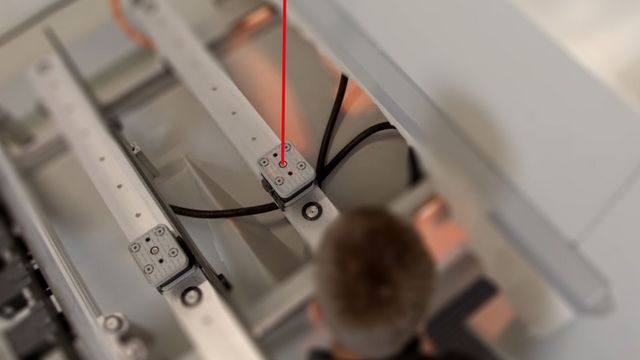

Laser pointers as standard feature

Laser pointers for exact position of the suction cups or for tracing the workpiece contours, attached on the right and left sides of the machining head.

Contour laser – the complete positioning solution

Contour laser – projects entire workpiece contour and all required vacuum suction cups simultaneously as well as all console positions without limitation for number of lines to be projected.

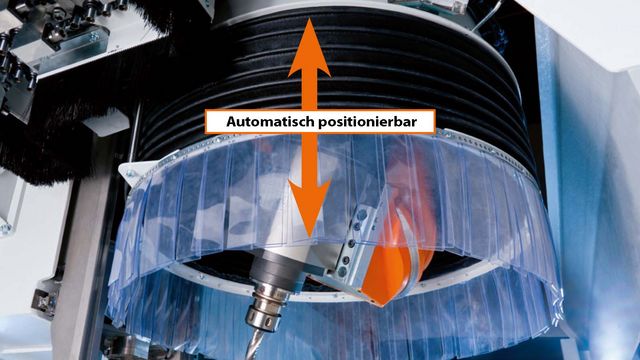

Flexible Evacuation

Flexible evacuation – programmable for eight positions

Fully automatic positioning in eight positions on machining head, for perfect adaptation of hood to workpiece height. This guarantees optimum evacuation of chips.

Mobile control panel

Ergonomic design of your workplace is of increasingly greater importance. HOLZ-HER offers a mobile control panel as a standard feature for all EPICON models. This control panel is equipped with a 21.5”, 16:9 multi-touch screen for perfect user convenience. The attached rollers allow the control panel to be positioned for optimum support of the working process.

Technical Details

Maximum efficiency with Holz-Her machine networking

HOLZ-HER realizes your production ideas within 20 minutes from the first mouse click to finished furniture with seamless machine networking.

Energy savings made easy

The intelligent ECO MODE energy management for HOLZ-HER CNC machines not only helps preserve our environment - it also saves you money.