Edgebander LUMINA 1380: Edgebanding for artisans at an industrial level.

Our new LUMINA 1380 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency.

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

Here is what the HOLZ-HER LUMINA series offers

- LTRONIC and GLU JET - invisible joints in double pack!

- iTronic for intelligent automation

- Workpiece Thickness up to 60 mm

- Edge Thickness up to 15 mm

Here is what the HOLZ-HER LUMINA 1380 offers

Technical Details

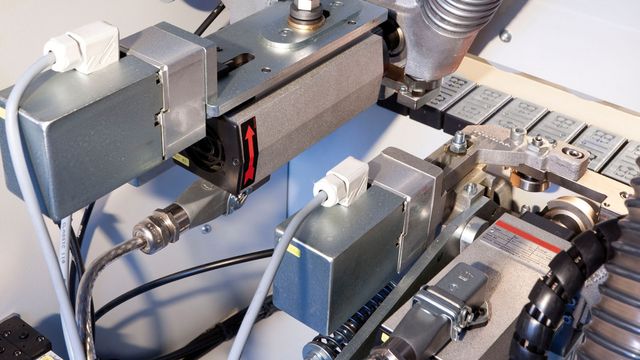

iTronic for intelligent automation

iTronic operating components

1. Adaptive trimming blade

Full adaptive trimming blades with automatic pressure adaptation to match edge thickness and height. Your advantages:

- Always the right pressure for different types of edging

- Prevents unnecessary vibration

- Reduces wear

2. Automatic pressure unit

The contact pressure of the individual pressure rollers is adapted perfectly to the application by an intelligent pneumatic system. Your advantages:

- Reduces reject quotas to a minimum

- Eliminate sample workpieces

- Optimum machining results even for continuously changing applications

3. Automatic glue quantity control

Automatic, requirement-adapted control of glue quantity with program selection: Always optimum glue application for:

- Various types of panels, e.g. chipboard or MDF

- Various panel thicknesses

- Various feed rates

- EVA or PUR glue

- Adaptation to processing parameters for glue from different manufacturers

4. Automatic cleaning routine

Integrated, fully-automatic purging routine for PUR glue at the touch of a button on the control. This process completely purges the machine, full automatically, with the correct quantity of cleaner, at the right temperature and contact pressure. (Cleaning is required after 48 h = PUR reaction time). Your advantages:

- Best system on the market

- PUR glue always under control

- Avoids errors during cleaning operation

5. Remaining glue quantity indicator

The remaining quantity of glue as well as the running meters that can still be processed are automatically monitored by a special sensor in the system and displayed to the operator on the control. Your advantages:

- Operator knows how many running meters can still be produced at all times

- Professional supervision of the cleaning process

- Optimization of remaining quantity of glue in system at time of cleaning process.

Edge Control

Edge Control

21.5" Touch screen color monitor with 16:9 format. High performance control with simply operation for rational machine set-up and change-over.

- 21.5" touch screen color monitor - standard feature.

- Graphic user interface, all information displayed in plain text and/or graphic form.

- Simple operation – rotating and swiveling control panel at eye height.

- Programs are simple to call with program names and numbers.

- Large program memory for all desired applications.

- Individual selection of units with the functions as basic setting possibilities for nominal values, path points and tool corrections.

- Service reports in clear text.

- Individual management for up to ten users with password protection and individual authorization.

- Network connectivity.

- Online maintenance, rapid exchange of data with HOLZ-HER service department.

- Barcode interface.

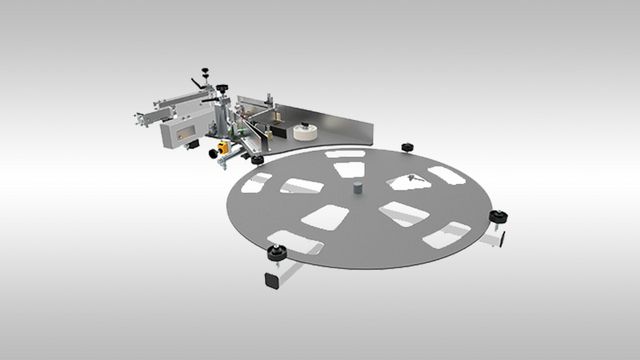

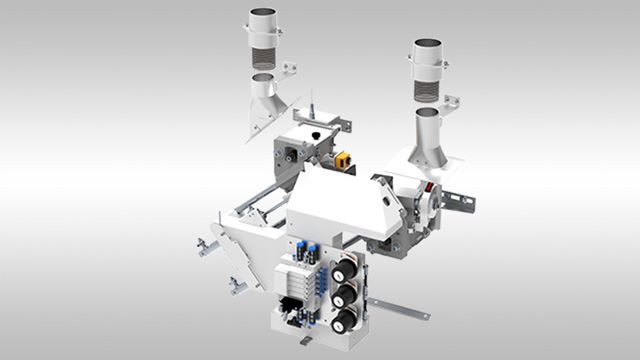

SYNCHRO edging feed

SYNCHRO edging feed

The edging magazine with synchro-drive. With its synchronous adaptation to the feed rate, this edging magazine guarantees short intervals between workpieces and simultaneously optimizes edging protrusions.

Small feed angle thanks to nozzle design - easy feeding of solid wood edging up to 15 mm.

Jointing cutter

- Including height adjustment for optimum utilization of cutters.

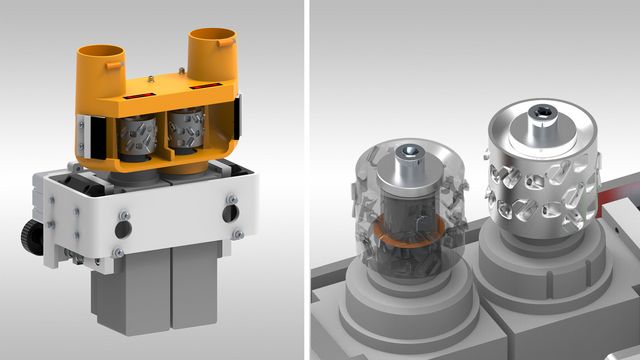

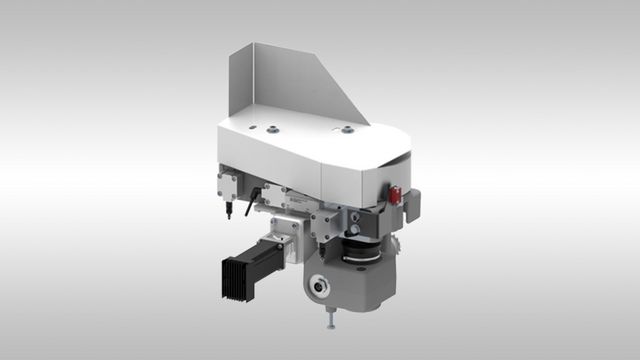

LTronic - laser edging change-over unit

LTronic laser edgebander

The LTronic laser edgebander was developed especially for the LUMINA series and processes all edging with functional layer on the market. Two different NIR modules are available for processing laser edging:

- NIR module for edge heights up to 23 mm (standard)

- NIR+ module for edge heights up to 45 mm (optional)

(NIR = Near Infrared Radiation)

Switch it on and it's immediately ready for use – the new Ltronic unit does not require a heat-up time or any heat-up phases during the machining process. In addition, the complete system operates absolutely silently which is a clear advantage for the user compared to other systems. Moreover, cleaning costs are minimal. The integrated protective plate on the NIR module needs to be briefly cleaned just once per week.

A highlight is the edging library completely integrated into the control. All of the very latest co-extruded and subsequently coated edging are already stored here as a factory-provided item and can be simply selected by the user via the standard touchscreen. Each laser edging needs a specific energy entry, which, by way of an example, depends on the edge thickness or the color. After the selection is made, Ltronic automatically adjusts the respective energy requirement. HOLZ-HER takes perfect care of all of that with its edging library.

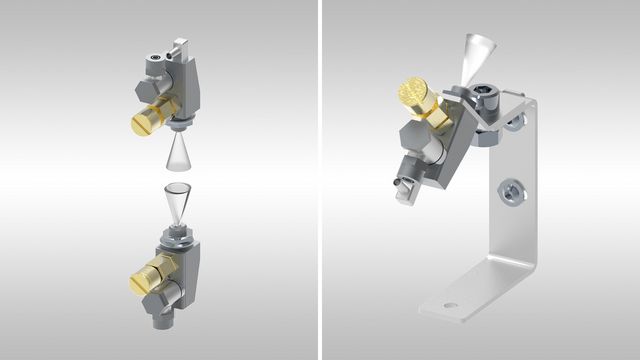

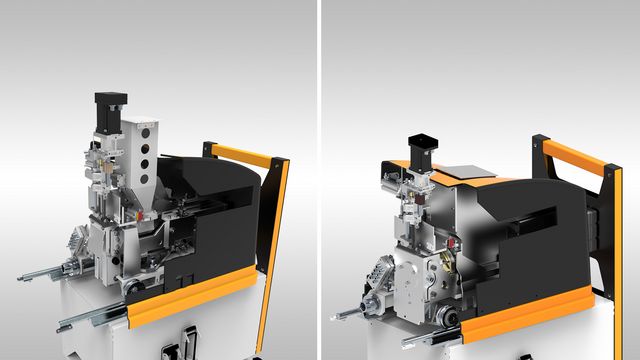

Glu Jet automatic - Change-over gluing station

The Glu Jet automatic can be configured as a change-over glue application system mounted on a set-up carriage for rapid change-over to the LTronic . Change-over can be completed in a few sections using a high precision interface with HSK chuck from our CNC technology.

- An optional feature is the “big brother”, the Glu Jet PUR 2K, which operates with low cost, standard commercially available 2 kg PUR glue cartridges. This unit pays for itself if you use more than approx. 500 kg of PUR glue per year.

- Moreover it can also process EVA glue. With a melting capacity of 12 kg per hour, it guarantees continuously optimal glue application without any glue discontinuities even at the full feed rate.

Both gluing stations are ready for use within 3 minutes.

Motor-driven pressure unit

Pressure unit with synchronous drive and automatic adaptation to feed rate. Straight and tapered pressure rollers for perfectly glued joints.

- With NC servo-axis for motorized adjustment to specific edge thickness (optional).

Pneumatic trimming unit

For straight or chamfered trimming on thin edging; a standard feature allows this unit to be pivoted to 10 degrees pneumatically. High quality version with stable cast iron pillars.

Sawing motors each with two guides for precisely trimming off protruding edging.

Pneumatic cutter unit

Multifunction cutter unit for flush cut on edging with thickness up to 8 mm, radiuses up to 3 mm, pivots 0-15 degrees. Including diamond tipped tools.

Further equipment: Integrated chip collection in tool, ProLock system.

- Also available as option: Fully automatic control with four NC servo-axes and automatic pivot adjustment.

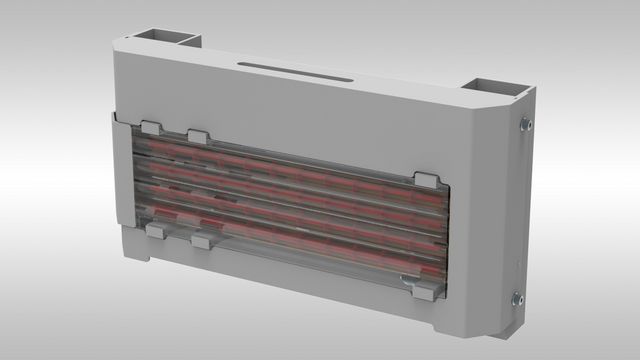

Scraper unit

For perfect smoothing of radiuses and chamfers on plastic edging. Also available with four NC servo-axes

Flat scrapers application controlled

Clean post-processing of surfaces. Application controlled with 2 HW cutting edges, for use on 4 sides. Completely eliminates all manual finishing.

Flat scrapers with pre and post-sensing

Clean surface finishing with pre- and post-sensing for high feed rates. 2 HW cutting edges, for use on 4 sides.

Buffing unit

Polishing for maximum gloss; for complete finishing. Standard setup.

Technical Details

Energy savings made easy

The intelligent ECO Mode energy management for HOLZ-HER edgebanders not only helps preserve our environment - it also saves you money.

Maximum efficiency with Holz-Her machine networking

HOLZ-HER realizes your production ideas within 20 minutes from the first mouse click to finished furniture with seamless machine networking.

Are You Already Saving?

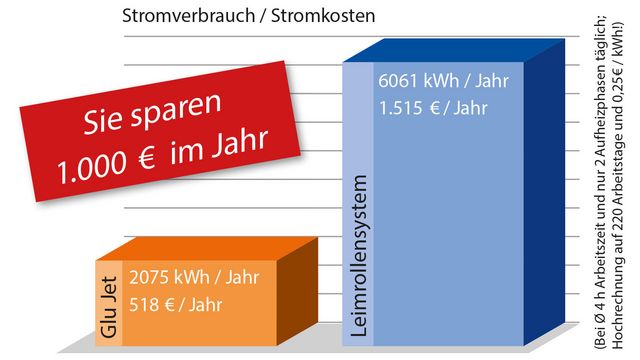

Are you still "rolling" glue or are you already saving? Savings of up to € 1,000 / year with our patented Glu Jet nozzle system.

References

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

Brochure LUMINA 1375 | 1380 (PDF, 5 MB)