Product data

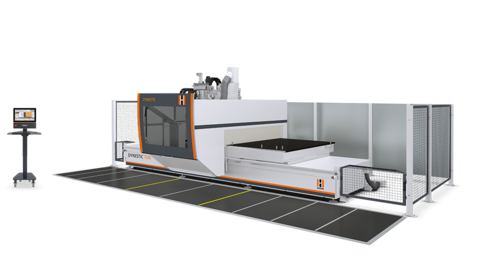

HOLZ-HER DYNESTIC 7535: Dynamic 5-axis machining in XXL format

The DYNESTIC 7535 CNC with 5-axis cutting spindle and a 2,200 mm deep grid table is the flagship of the new series with nesting machines made by HOLZ-HER. Even with this huge working depth, the moving stands in solid gantry design ensure utmost precision and optimum cutting results via two synchro drives.

The DYNESTIC 7535 is equipped with the completely newly developed CAMPUS software package version 7. The functionality and nesting result of the optional BetterNest software are really impressive. The high-flow nesting table ensures optimum vacuum flow and can also be supplied with an intelligent 16-field grid table and software-controlled vacuum control. Double-acting suction pads enable the clamping of doors, staircase components, etc., making this 5-axis CNC machine a real all-rounder with virtually unlimited machining options.

The DYNESTIC 7535 makes it possible to process lengths greater than 6 meters. The liquid-cooled 5-axis precision cutting spindle is already supplied as standard with 10 kW power and a speed range of 1,000 – 24,000 rpm on all HOLZ-HER 5-axis machining centers. The high-performance 12 kW cutting spindle or the 17 kW PRO-TORQUE spindle with controlled axis locking is available as an option.

Whether as a DYNESTIC 7535 classic, push, automatic or lift – this 5-axis CNC machine sets standards!

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

Here is what the HOLZ-HER DYNESTIC series offers

Here is what the DYNESTIC 7535 offers

- Automation components

- Solid gantry design

- Machining in Y direction: up to 2,200 mm

- Machining in X Direction: Up to 3,700/4,600/6,250 mm

Technical Details

Powerful 5-axis cutter unit

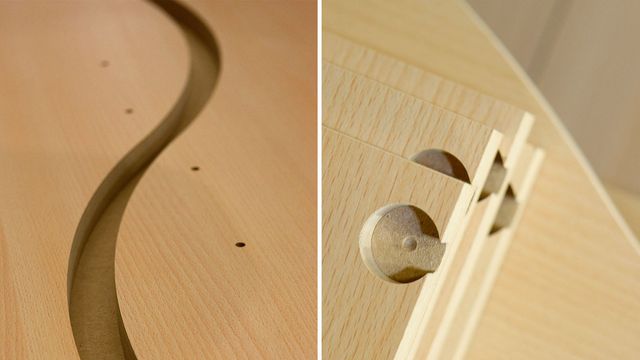

The "fifth dimension" in woodworking

The gimbal-mounted machining head with up to 18 kW (standard 13 kW) ensures precise guidance for complex curled or curved parts such as stair railings or furniture or model shapes with complicated design. The compact, powerful and fully interpolating machining head operates at speeds up to 24,000 rpm its ceramic bearings and liquid cooling allow it to work under extremely high loads.

The special feature of the optional 18 kW spindle (S6) is the PRO-TORQUE technology, which automatically locks the A and C axes mechanically, allowing extremely high torque at the spindle. Optimum evacuation is achieved by the evacuation hood with 8 adjustment positions.

"BetterNest" - the optimum nesting software

Innovative operator software for optimized cutting and processing

The increasing popularity of nesting technology as a combined cutting and CNC processing solution for large quantities of panels has also increased the requirements placed on the nesting software. For this reason, HOLZ-HER offers the "BetterNest" software as an auxiliary module for the CAMPUS / NC Hops software for the functional nesting machining centers in the DYNESTIC series.

This module is available for pure rectangular nesting or as a free-form version with a completely new type of algorithm offering never-before-achievable nesting results with cutting losses far below that obtained with conventional nesting software. In combination with its simple operation in spite of its enormous versatility, it significantly facilitates programming for users in the office and on the machine while ensuring maximum process reliability.

Highly flexible nesting technology

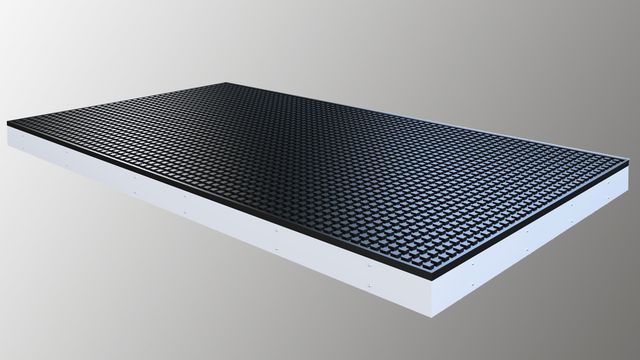

High-flow nesting table

Nesting technology for rational production. With the nesting process, a porous protective panel – usually a thin MDF panel – is held down on the machine table by a vacuum. It provides a large surface for suction and serves to support the workpieces to be processed. Nesting technology allows optimized processing and cutting of panel materials.

- For formatting nesting cutting plans on the nesting table.

- Workpieces can be processed with manually positioned suction cups.

- The HOLZ-HER nesting table has small matrix dimensions – of only 50 mm – to ensure maximum vacuum flux over the entire table surface.

Integrated drilling head

The PRO-MASTER is perfectly equipped with drilling heads for optional integration.

16 Spindles

- Drilling unit with 10 vertical spindles (X = 6 / Y = 4)

- Six horizontal spindles (two double drilling spindles in X direction / one in Y direction).

- Integrated grooving saw in X direction.

- The pressure booster included as a standard feature provides even more power for the drilling unit.

24 Spindles

- Drilling unit with 18 vertical spindles (X = 11 + 2 / Y = 6)

- Six horizontal spindles (two double drilling spindles in X direction / one in Y direction).

- Integrated grooving saw in X direction.

- The pressure booster included as a standard feature provides even more power for the drilling unit.

Focused flexibility

- With 14 tool positions the standard linear tool changer is well equipped.

- 1-position X/Y Pick-Up tool changer for transfer of angle gear to spindle in X/Y direction.

- Instead of linear changer an 18-position traveling disk tool changer can be ordered. This is perfect e.g. for 2-field processing in pendulum mode.

TouchTool tool length measurement

TouchTool is the perfect system for the tool length measurement and updates the appropriate values in the tool database. Additionally Touchtool enables an early realization of tool breakage.

TouchProbe workpiece measurement

The precision measuring probe TouchProbe measures workpiece length, workpiece depth and material thickness with its ceramic ball caliper and transmits the data to the control of the CNC machine. Thereby measuring errors in the program are automatically updated.

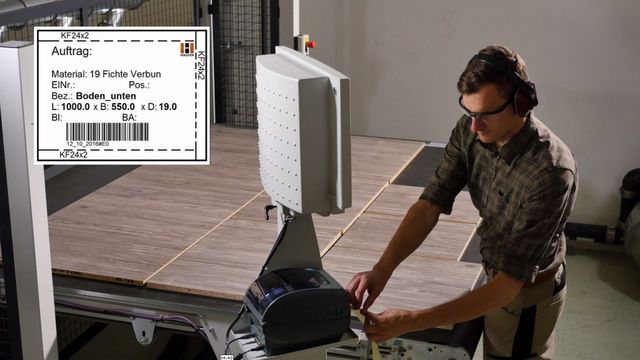

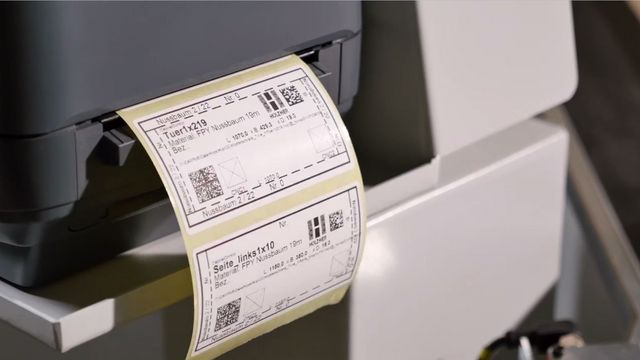

TouchLabel - overview of labels

TouchLabel - the perfect solution for labeling

The 21,5" touch screen provides a perfect overview of the nesting results. Simply tap the workpiece and the label printer included in the package prints out a self-adhesive barcode label.

The integrated CAMPUS module label printer allows printout of normal text as well as barcodes (barcode and 2D data matrix). Naturally, your barcode labels can be adapted to your specific requirements with the label template editor.

Direct Label - integrated fully automatic label printer

The industrial printer unit Direct Label is installed in a user-friendly protective housing in the moving column of the nesting machine. Label positions are generated and transferred fully automated via the CAMPUS machine software and the BetterNest nesting software.

The machine picks up the labels one after the other via a 90° rotating stamp on the printer and positions them fully automated on the raw plate before the nesting processing. Both normal text and barcode printouts (barcode and 2D data matrix) are possible. A label template editor for linking to label variations is integrated as well.

Power Label for more labelling throughput

Power Label for more labelling throughput The HOLZ-HER Power Label System is therefore recommended for high panel throughputs.

The Power Label automatically applies the right labels to the right position on the panel - even before further processing in the Nesting CNC machine. This enables fast and efficient marking of your workpieces, fully automatically and without manual intervention.

Right-hand operation for individual space conditions

For the perfect adaptation to your individual space conditions, all automated variants of the DYNESTIC 7532 and 7535 models are available, in addition to the classic left-hand operation, as right-hand machines for the production sequence from right to left.

The perfect solution for your material range

One machine - unlimited possibilities

Due to their flexible options the DYNESTIC models are perfectly designed for the processing of many different materials. The processing of sensitive and heavy materials is enabled because of air buffers. "ColdGun"is suitable for synthetic material, aluminium and composite materials. Due to this "ColdGun" the workpieces and milling tools stay constantly cool. Because of that this option enables extrem long tool lifetimes. Amongst others the following materials can be processed with the DYNESTIC models

- Plexiglass

- Plastics

- Solid surface

- Aluminium composite material

- Alu Core

- Alu Profile

- Panels

- MDF panels

- Solid wood glueboards

Excellent operator ergonomy

The ergonomic design of your workplace is constantly growing in significance. HOLZ-HER offers a control desk, which was developed specifically for the DYNESTIC series. This control desk is equipped with an 21,5" and 16:9 monitor and ensures perfect operator ergonomics.

Depending on the machine equipment the operator desk can be chosen optionally with a mobile base. The wheels enable to move the desk to the place, where it is most suitable for your working process.

Definitely the full usage

The possibility to strike the workpieces optionally on the front stop bar, makes the DYNESTIC series even more flexible. Formatted workpieces can be positioned and processed easily and precisely. Special vacuums for the grid table allow e.g. horizontal drilling and profile processing on different workpieces.

Efficient vacuum technology

Extremely high performance, efficient vacuum pumps ensure workpiece is held securely. These low maintenance, dry-running pumps are also distinguished by their low noise emissions and extremely low maintenance requirements.

Moreover, our intelligent ECO VAC vacuum control uses a software program to ensure that the required vacuum power is always present when several pumps are used.

Technical Details

Maximum efficiency with Holz-Her machine networking

HOLZ-HER realizes your production ideas within 20 minutes from the first mouse click to finished furniture with seamless machine networking.

Energy savings made easy

The intelligent ECO Mode energy management for HOLZ-HER CNC machines not only helps preserve our environment - it also saves you money.