CNC Machining Center EVOLUTION 7405 4mat: Complete CNC Machining in Compact Format

The EVOLUTION series offers unique patent-pending solutions for complete processing of your workpieces. Distinguished by well-thought-through industrial design and extremely stable layout.

Unique in its class, the EVOLUTION 7405 4mat offers absolutely precise edge routing on all four workpiece edges and thus complete formatting for panel material.

The technical data for the EVOLUTION speaks for itself: A vertical pass-through dimension of 1,200 mm combined with unlimited longitudinal processing and minimum space requirements. Material thicknesses of 8 to 70 mm make the vertical machining centers from HOLZ-HER all-round machines for producing everything from drawers to body parts, furniture fronts and rear walls; in short complete machining of all your products. Above all the EVOLUTION 7405 4mat guarantees short cycle times and extreme precision, because workpieces with lengths up to 1500 mm can be machined without reclamping. The solid design of the EVOLUTION series guarantees you maximum machining quality.

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

Here is what the HOLZ-HER EVOLUTION series offers

Here is what the HOLZ-HER EVOLUTION 7405 4mat offers

Technical Details

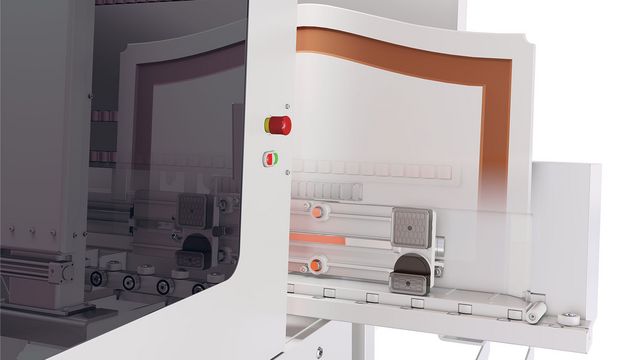

Doors Ready - The optional door package

The EVOLUTION models are now more versatile than ever in terms of workpiece height thanks to an increased passage size of 1,200 mm.

The optional EVOLUTION door package, consisting of a specially developed angle gear for lock boxes and a lock box cutter, expands the capabilities of this vertical CNC machine from HOLZ-HER.

The door package allows complete machining of door leaves with a maximum thickness of up to 70 mm. This process machines the hinge side and lock side in two clamping operations. The 16 mm dia. shat cutter allows a cutting depth of up to 115 mm making it possible to cut lock boxes with different bolt dimensions. Handle and lock holes can also be drilled precisely using HOPS macros. After turning and reclamping the door leaf, it is possible to recess hinges for rabbeted doors as well as install concealed hinges or fittings for object doors.

3-axis Clamex package for the 7405 4mat

With the EVOLUTION 7405 4mat you are free to choose your connection technology

In addition to drilling dowel holes and countersinking Cabineo connectors, the macros included with the EVOLUTION 7405 4mat with 3-axis Clamex tool set, also allow you to cut pockets for Lamello Clamex connectors in the X and Y directions, as well as in all four edges of the workpieces. You decide which connectors you need for your application.

EVOLUTION for Doors - Door machining for practical carpenters

The EVOLUTION door package is perfect for practical use in machining doors. In addition to cutting lock boxes, latch holes and hinges, the package provides features to mill cutouts for door closers and draft blockers. This package offers modern carpenters everything they need to produce doors. Maximum benefit in only 5 square meters of floorspace.

xcut package for optimum strip processing

Simple. Efficient. Cost saving - From panel strips to finished furniture.

With the xcut package the EVOLUTION automatically produces the required workpieces from panel strips previously cut in the longitudinal direction. This xcut mode completely eliminates cross-cuts otherwise required.

The xcut software lists all pending jobs on the machine monitor. This provides the machine operator with a perfect overview of all jobs. The strips are cut to the precise length, milled on 4 sides and drilled as required. This process ensures that the entire surface of the panel strips is utilized optimally.

In the so-called edge mode, you can also format the length of already edged strips without tearing. This makes the EVOLUTION 7402 and 7405 with optional xcut package a center for efficient carcass production.

xcut Highlights

- xcut table – Extended entry table for secure guidance of long panel strips.

- Workpiece database – “Warehouse” including open CSV interface Hop import and sorting feature.

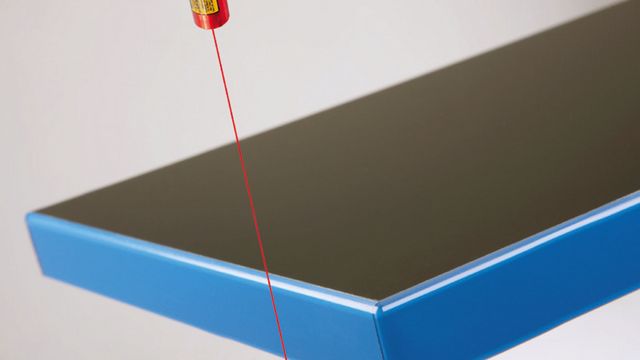

- Laser measurement – Automatic measurement of strip width and length with remnant recognition.

- Automatic formating – Length and width formating with X and Y milling.

- Part identification – Simply read in workpiece programs and mark using optional barcode scanner and Easy Label printer with labeling software.

4mat means complete processing

Complete processing on all 4 sides with lengths up to 800 mm without reclamping

- Simply adjust the bottom jointing dimension – the rest is accomplished automatically.

Significantly shorter machining times

- while maintaining maximum precision and machining quality.

Generous machining dimensions

- Height up to 920 mm and length up to 2,500 mm without additional supports. And still extremely space-saving and compact.

Fully automatic thickness adaptation for workpieces from 8 to 70 mm

- Ideal for rear walls, sides, fronts and even kitchen counter tops. These can be processed in any length in workshops with appropriate space and safety intervals.

Performance package

Complete machining – convincingly good

The EVOLUTION 7405 4mat offers truly unique features. Precise edge routing on all four workpiece edges allows panels to be formatted completely. The result is perfectly formated workpieces completely grooved and profiled on all edges.

With the Performance package upgrade to the 10.3 kW HSK spindle with tool changer for 6 tools, the machine also allows profile milling, point thinning, engraving, etc. with automatic tool change in this machine class. The EVOLUTION 7405 4mat is therefore a full value machining center ready for implementation of an infinite variety of design ideas.

- Complete processing on all 4 sides in one clamping operation with the EVOLUTION 7405 4mat. Simply adjust the bottom jointing dimension – the rest is accomplished automatically.

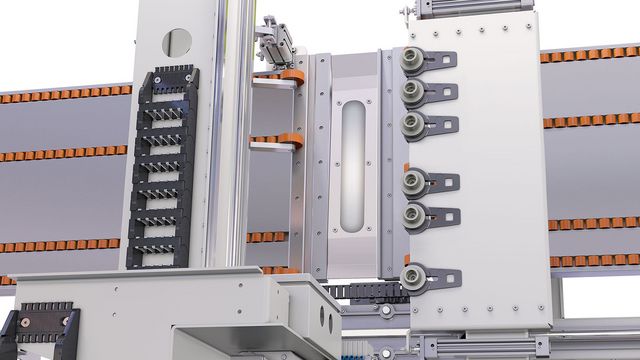

Unique clamping concept

Fully automatic positioning of suction cups. Automatic contact pressure independent of material thickness for optimum results and precise dimensions.

Whether panel material or solid wood: The automatic vacuum clamping system on the EVOLUTION Series ensures a secure hold while handling the material gently.

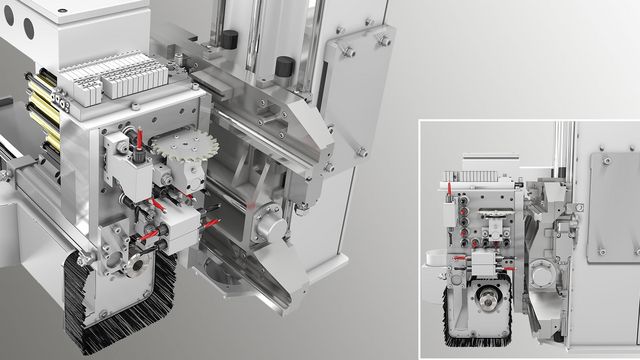

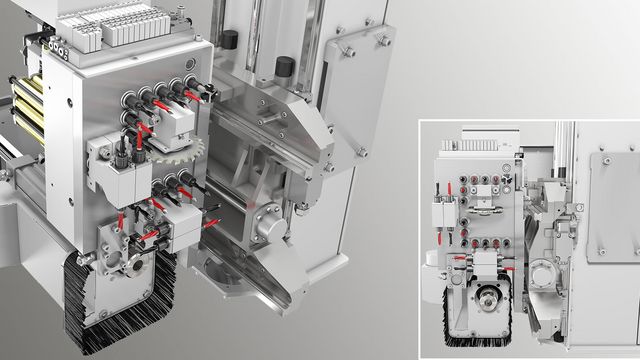

Perfectly equipped - standard drilling head

15 drilling spindles for 5 in-line holes each in X and Y directions as well as 6 horizontal drills and integrated sawing unit for quick and precise results. As an option, the EVOLUTION series can also be equipped for even higher performance with an XL-drilling head, with up to 22 drilling spindles and grooving saw.

Extra large XL drilling head

For even more drilling power - also with XL drilling head

Thanks to the XL drilling head, the range of applications and the enormous versatility of the vertical machining center is further increased. Equipped with up to 22 spindles, the head can be generously equipped for drilling rows of holes, structural and through-holes - reducing time-wasting drill changes.

Above all the possibility to equip the head with an additional double-drilling spindle in the Y direction and an extra strong spindle for hinge drill bits brings a unique level of flexibility. This allows 5 mm and 8 mm holes to be drilled in the sides in both X and Y directions – flexibility to your advantage.

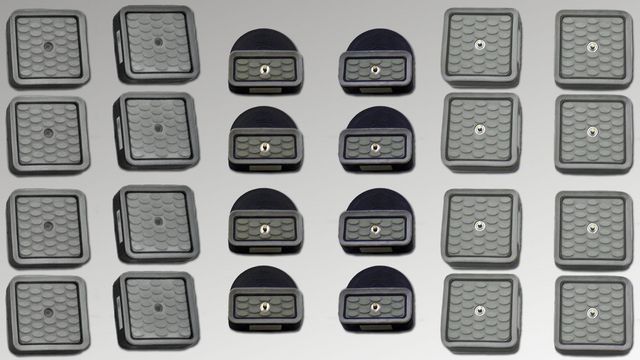

For holding all types of material

HOLZ-HER offers a variety of special suction cups for various types of material and processing requirements. This makes the EVOLUTION series even more versatile.

Standard suction cups with and without sensing valve

- Ideal for processing panels

Solid wood suction cups

- Ideal for extremely heavy workpieces and applications with solid wood

Quick change-over

- You can change over your EVOLUTION machine for use on special materials within the shortest possible time.

Automatic tolerance correction

Determination of exact length dimension and automatic correction of tolerances for dimension-dependent drilling. Perfect optional supplement for high precision drilling, e.g. for workpieces which have already been edged.

Shorter processing times

Easy on material and time-saving, because workpieces with lengths up to 1,500 mm can be machined without reclamping.

- Up to 35% shorter machining cycles.

Unique Pic2Plate Software

HOLZ-HER offers the unique, patented Pic2Plate software allowing image data to be copied and vector cutting programs to be generated quickly and easily (optional on 7405 4mat and 7405 Connect).

- Supplement your product portfolio to include light-reflex engraving with depth effect.

- Generate unique visible and tactile works of art on your HOLZ-HER EVOLUTION CNC.

- A normal photo or scan is all you need to create works of art in just a few steps for many types of applications and from different types of panel materials.

- The Pic2Plate-Software is easy as pie to use!

- The integrated post processor guarantees seamless transfer of the milling data to your HOLZ-HER CNC using CAMPUS software.

Technical Details

Energy savings made easy

The intelligent ECO MODE energy management for HOLZ-HER CNC machines not only helps preserve our environment - it also saves you money.

Maximum efficiency with HOLZ-HER machine networking

HOLZ-HER realizes your production ideas within 20 minutes from the first mouse click to finished furniture with seamless machine networking.

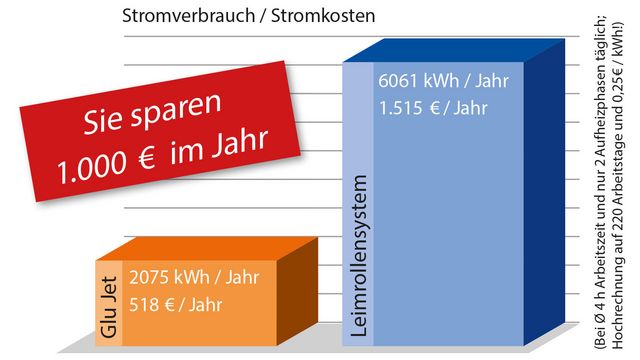

Are you already saving?

Are you still "rolling" glue or are you already saving? Savings of up to € 1,000 / year with our patented Glu Jet nozzle system..

References