CNC Machines EPICON Series: The high power universal geniuses

Enter the next generation of CNC woodworking with HOLZ-HER’s EPICON Series . The EPICON 5-axis CNC machine opens up new horizons for implementing your creativity.

The optimized design of the EPICON CNC machining centers offers the ideal basis to ensure absolute precision and perfectly machined workpieces while simultaneously allowing extremely high acceleration and cutting rates.

To this we have added our high precision direct servo-drive, wear-free couplings and covered, precision linear guides - all covered by our 10 year HOLZ-HER guarantee.

With its proven 5-axis technology and fully interpolating 13 kW, 5-axis spindle (as standard features) this machine guarantees extremely high drive holding forces.

The EPICON series is completed by a versatile and comprehensive range of optional equipment to satisfy all desires, allowing the EPICON to be configured optimally for applications in the fields of furniture production, staircase construction and model making as well as machining solid wood.

All machines

CNC machining center EPICON 7135 SpaceSaver

The 5-axis space-saving miracle

- Powerful 5-axis spindle

- Enclosed vacuum pump

- Flexible table concepts

- Full Bumper security technology

- Permanently mounted switch cabinet

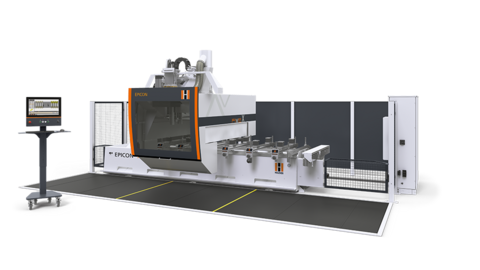

EPICON 7135 CNC machining center

Perfectly equipped for all machining work

- With 5 interpolating axes

- Multifunction Machining Head

- Machining in Y direction: up to 1,500 mm

- Highly Flexible Table Concepts

- Extreme Acceleration Values

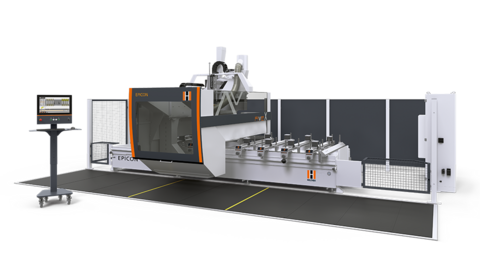

CNC machining center EPICON 7235

Powerful all-purpose genius for any workshop

- Solid gantry design

- With 5 interpolating axes

- Multifunction Machining Head

- Machining in Y direction: up to 1,650 mm

- Highly Flexible Table Concepts

EPICON 7335 CNC machining center

The convincing 5-axis wonder for optimum results

- Solid gantry design

- With 5 interpolating axes

- Multifunction Machining Head

- Machining in Y direction: up to 2,100 mm

- Highly Flexible Table Concepts

Here is what the HOLZ-HER EPICON series offers

- CAMPUS Machine Control

- With 5 interpolating axes

- Effective machining height up to 300 mm

- 10 year guarantee on all linear guides

- Machining in X direction: up to 7,280 mm

- Machining in Y direction: up to 2,100 mm